Strato Riflettente in Argento per Prestazioni Superiori

Le significative differenze di prestazione tra gli strati riflettenti in argento e quelli in alluminio evidenziano l'importanza di sapere cosa si sta acquistando.

Il materiale utilizzato per lo strato riflettente di un CD o DVD vuoto è un fattore critico nel tasso di fallimento del disco. Lo strato riflette il raggio laser verso il fotosensore del laser nella testina laser, quindi se questa riflessione non è precisa e costante, il disco presenterà errori durante la scrittura o la lettura dei dati.

Lo strato riflettente è generalmente realizzato in alluminio o argento. I dischi con strati riflettenti in alluminio sono generalmente più economici, mentre gli strati in argento offrono una riflettività superiore, che può migliorare le prestazioni di lettura e scrittura. È necessario comprendere l'importanza di questi miglioramenti delle prestazioni e se giustificano la differenza di prezzo.

Inoltre, nella valutazione, è necessario notare che i laser nei drive ottici si deteriorano nel tempo e diventano meno potenti. È quindi rilevante capire come si comportano i dischi ottici in drive relativamente nuovi e in quelli più vecchi.

ALTO TASSO DI FALLIMENTO DELL'ALLUMINIO

Nei test con nuovi drive ottici (meno di un anno), il tasso di fallimento nella masterizzazione dei contenuti sui dischi in alluminio era superiore al 10% per i DVDR e oltre il 13% per i CDR, rispetto a zero fallimenti per l'argento. Tuttavia, quando utilizzati su drive ottici più vecchi (oltre un anno), il tasso di fallimento nella masterizzazione era notevolmente più alto - oltre il 15% per i DVDR e oltre il 25% per i CDR, ancora una volta rispetto a un tasso di fallimento zero per l'argento. Inoltre, nei test del tasso di errore, i prodotti con strato in argento si sono comportati tutti entro le specifiche (DVD: PI sum8<280 e CDR: C1<220) mentre tutti i dischi in alluminio erano fuori specifica, con errori significativamente più alti registrati nei test su drive ottici di oltre un anno.

Queste differenze di prestazione possono essere attribuite direttamente alla riflettività inferiore dello strato in alluminio rispetto a quello in argento.

CORROSIONE

I supporti ottici sono anche suscettibili alla corrosione, particolarmente durante il trasporto via nave dove possono essere esposti a temperature elevate e umidità. L'alluminio si ossida a contatto con l'ossigeno dall'ambiente o con l'umidità penetrata nel disco, riducendo la sua riflettività e rendendo il disco illeggibile dal laser, fenomeno a volte chiamato "rot" del disco. L'argento può anche perdere riflettività con la corrosione dovuta all'esposizione al diossido di zolfo, un inquinante ambientale che può migrare attraverso il disco con l'umidità. Tuttavia, il Test di Affidabilità ha dimostrato che tutti i prodotti in argento hanno superato la prova di 100 ore di calore e umidità, che verifica la durata di esposizione durante la spedizione e lo stoccaggio e anche le capacità di archiviazione. Al contrario, tutti i CD e DVD in alluminio non hanno raggiunto le 100 ore.

TABELLA - Tassi di Difetti per Supporti Ottici con Strati Riflettenti in Alluminio o Argento

| CD-R Alluminio | CD-R Argento | DVD-R Alluminio | DVD-R Argento | |

|---|---|---|---|---|

| Tasso di Fallimento nella Masterizzazione (Drive < 1 anno) | >13% | 0% | >10% | 0% |

| Tasso di Fallimento nella Masterizzazione (Drive > 1 anno) | >25% | 0% | >15% | 0% |

| Tasso di Errore | Tutti fuori specifica | Entro specifica | Tutti fuori specifica | Entro specifica |

| Test di Affidabilità (80°C/80%RH) – 100 ore (*Simulato per 1 anno di longevità) | Fallito | Passato | Fallito | Passato |

Fonte: CMC Quality Comparison Test

SCEGLI L'ARGENTO

Quando si acquista un supporto vuoto, il materiale utilizzato per lo strato riflettente potrebbe non essere mai considerato, ma è chiaro da questa analisi che è un attributo chiave e dovrebbe essere parte dei criteri di selezione. La riflettività inferiore dell'alluminio comporta tassi significativi di fallimento nella scrittura e nella lettura, che peggiorano ulteriormente con l'uso di drive ottici più vecchi con laser più deboli. I dischi in alluminio hanno anche maggiori problemi di corrosione, e un altro problema noto con i dischi in alluminio è che diventano più caldi durante l'uso, accelerando il decadimento della testina di lettura del drive ottico.

Quindi, quando si acquista un supporto ottico, sebbene possa esserci una piccola differenza di prezzo, è sempre consigliato scegliere l'argento.

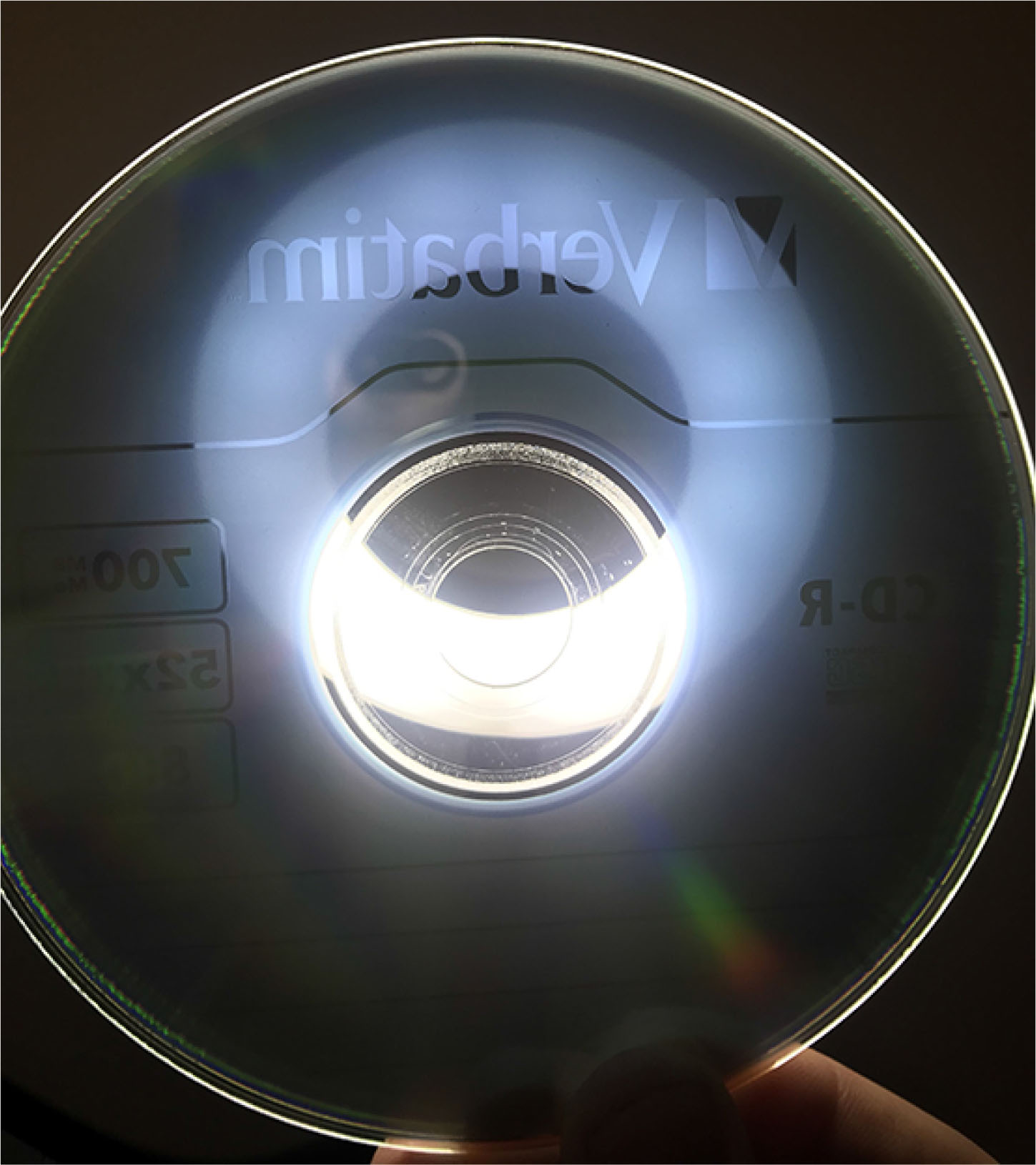

Identificare i dischi con strati riflettenti in argento o alluminio

|

|

A sinistra: Gli strati riflettenti in argento sono leggermente trasparenti.

A destra: Lo strato riflettente in alluminio è opaco.

Note:

- Errore PI (PIE): Un errore di byte si verifica quando uno o più bit in un byte hanno un valore errato rispetto al loro valore originale registrato. Una riga di un blocco ECC che ha almeno 1 byte in errore costituisce un errore PI. In qualsiasi gruppo di 8 blocchi ECC consecutivi, il numero totale di errori PI prima della correzione non deve superare la specifica di 280.

- Test di affidabilità: I risultati rappresentano un'esposizione continua a livelli estremi di temperatura/umidità. I tassi di errore non sono rappresentativi dei dischi conservati in condizioni tipiche, normali o ideali. I risultati di questi test servono a dimostrare, in termini di tassi di errore, la capacità di alcuni supporti DVD e CDdi rimanere stabili anche se esposti a condizioni estreme.